Prototek Offers Sheet Metal Prototypes

Parts in days anywhere in the USA.

Our Metal Prototyping services include:

- Facilities Throughout the USA

- Bending & Forming, Laser Cutting, Waterjet Cutting, Welding, and Assembly

- Fabricated Metals, Plastics, and Other Materials

Quality Matters | AS9100D Certified, ISO 9001:2015, ISO 13485:2016, & ITAR Registered

*Not all locations have all certifications and registrations. Parts requiring these will be made at facilities with the correct credentials.

Prototek is a valuable resource for those looking for sheet metal prototypes. Our services are fast, reliable, and offer quality results. We use state-of-the-art equipment to create precisely accurate and durable prototypes. Prototek caters to businesses from all industries and sectors, offering custom sheet metal bending and forming services and rapid prototyping. Their online quote system streamlines the ordering process, allowing customers to upload design files and specifications quickly and easily. Prototek’s engineers and technicians also help customers with design and material questions, ensuring that the final product meets their needs. Prototek is an excellent choice for anyone needing online sheet metal prototypes.

Our Online Process is Simple

2. Production

3. Quality Control

4. Delivery

About our Sheet Metal Capabilities

What is Sheet Metal Fabrication?

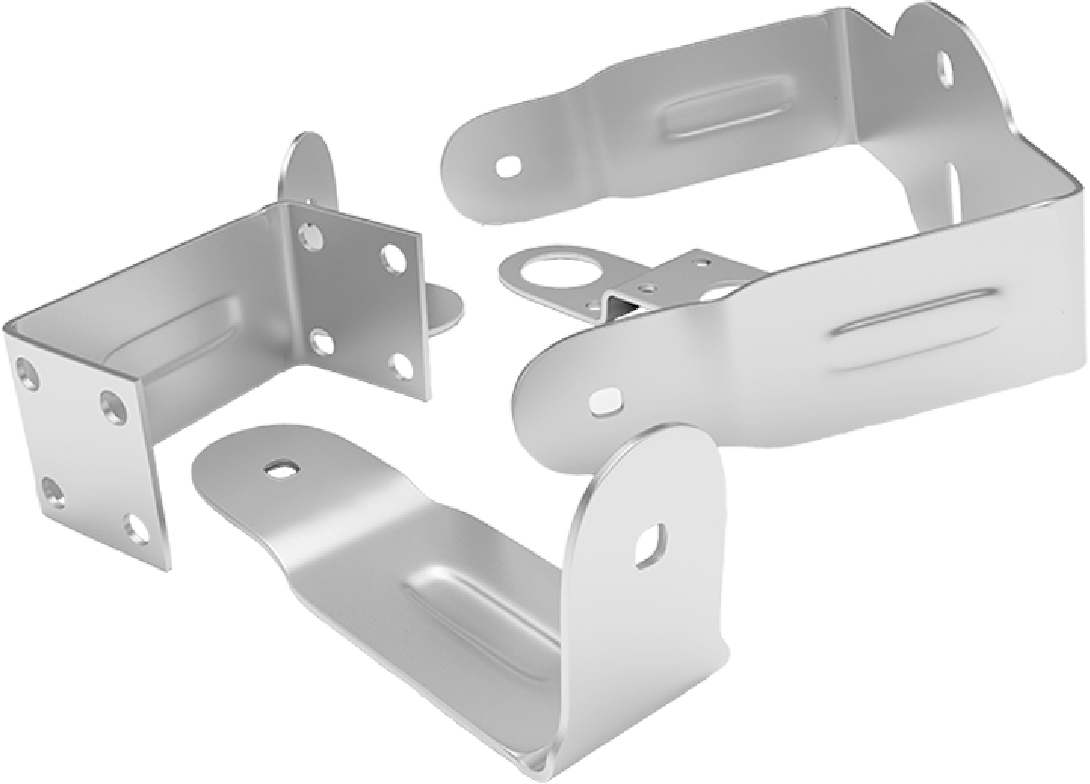

Sheet metal fabrication transforms metal sheets into prototypes or finished products using techniques like cutting, bending, & shaping. It’s used in many industries, like household appliances, construction materials, aircraft parts, signage, etc. The process begins with selecting a metal sheet, cutting it into the desired shape, and subjecting it to various treatments for a durable product, including bending, stamping, rolling, and welding. Sheet metal fabrication is cost-effective and can produce complex geometries.

Customize like never before.

Experience unparalleled accuracy by customizing every curve and corner. Test your prototypes in real-world conditions and choose from a variety of materials and finishes to match your needs.

Strength and durability.

The sheet metal prototype’s strength and durability depend on material type, thickness, fabrication method, and design. Steel, aluminum, and copper have high strength. Thicker sheets are better. Bending, stamping, and welding affect strength and durability. Design affects stress, deformation, and fatigue. Consider material, thickness, method, and design for desired specifications.

From prototype to performance.

Sheet Metal Prototyping can accelerate your project’s development with its swift, flexible, and reliable design iterations, testing functionality, and shift from concept to market with speed.

Sheet Metal Prototyping Capabilities

We offer sheet metal prototyping services for various industries. Our skilled engineers and technicians use advanced equipment to create high-quality products from different materials. We can produce anything from simple brackets to complex structures. Our services include design and engineering support, metal cutting, bending, punching, welding, painting, and finishing. We also offer rapid prototyping and low-volume production. Our team provides cost-effective and reliable solutions that meet our clients’ quality, performance, and turnaround time needs.

Bending & Forming

OEM:

Amada and Birmingham

Lead Time:

1 – 15 Days

Max Dimensions:

61 x 0.1345 in (10 Ga.)

Roll Length & Diameter: 4 – 3/4 in

(capacity based on Mild Steel)

Pinch Adjustment: Standard

Laser Cutting

OEM:

Amada, Beam Dynamics, Epilog, IPG

Lead Time:

1 – 15 Days

Max Dimensions:

61 x 99 x 11.8 in

Waterjet Cutting

OEM:

Flow

Lead Time:

1 – 15 Days

Linear Straightens: ± 0.0021 in

Repeatability: 0.0014 in

Sheet Metal Prototyping Materials

Prototek offers a variety of sheet metal fabrication materials, including stainless steel, aluminum, copper, brass, and galvanized steel. These materials have various properties, and our experts can help clients choose the right one for their prototyping projects.

Aluminum fabricated through sheet metal is a popular choice across several industries because of its durability, lightweight, and elegant appearance. Due to its corrosion-resistant and rust-resistant properties, it is used in the construction of aircraft, automobiles, appliances, and electronics. The fabrication process allows customization of the final product, ensuring that it meets the exact specifications of the customer. The end product is strong, malleable, and suitable for various applications.

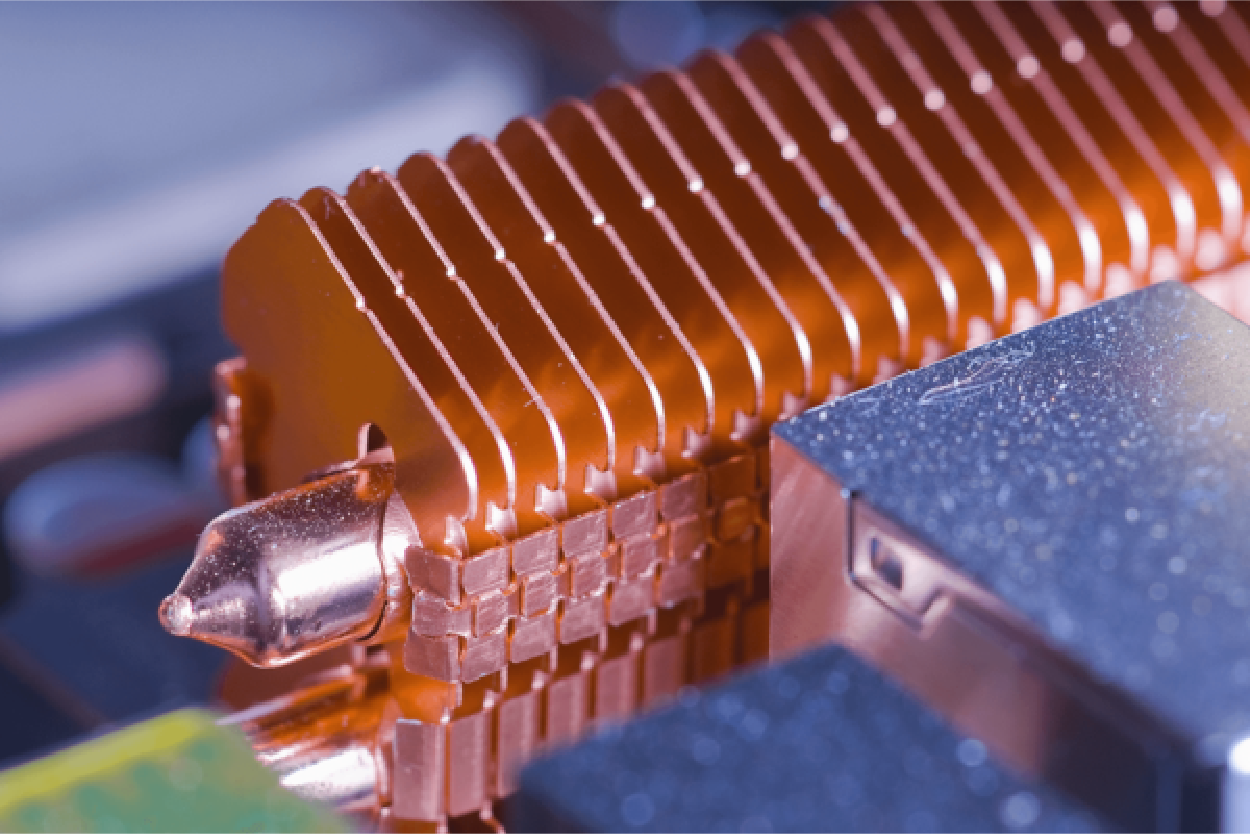

Copper is ideal for fabrication due to its excellent ductility and malleability. Sheet metal fabricated copper is used in roofing, plumbing, electrical systems, and electronics. The process involves cutting and shaping copper sheets to a specific size and welding and soldering them. The result is a material with excellent thermal and electrical conductivity, which makes it ideal for use in the electronics and electrical industries. It is also corrosion-resistant and can be finished with various treatments to enhance lifespan. In summary, sheet metal fabricated copper is versatile in multiple industries and applications.

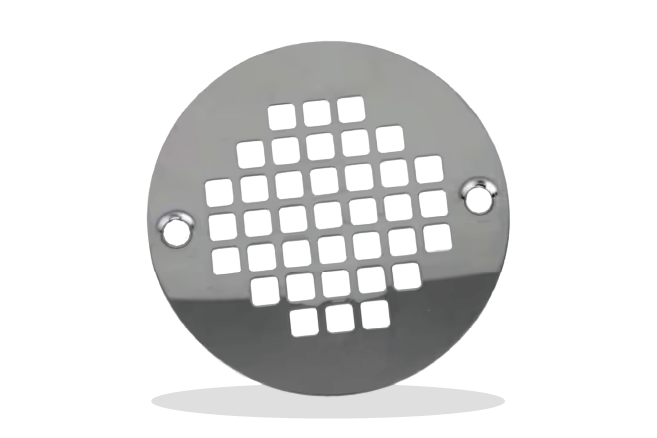

Stainless steel sheet metal is a strong and corrosion-resistant material made by adding chromium to steel, forming a protective layer. Fabrication involves cutting, bending, and welding sheets to create desired shapes. Due to its durability, versatility, and aesthetic appeal, it’s low maintenance and is used in various industries, including automotive parts, industrial equipment, and building components.

Sheet metal fabricated from titanium is commonly used in sheet metal fabrication. This is because it is lightweight, has excellent strength, and is corrosion-resistant. It is widely used in various industries such as aerospace, military, medical, and industrial that require components with high strength-to-weight ratios. Titanium’s unique properties make it an ideal material for applications subject to high heat.

Why choose Prototek for your next sheet metal prototyping project?

Choose Prototek for your next sheet metal prototyping project. With over 30 years of experience, state-of-the-art equipment and skilled employees, Prototek provides precision metal fabrication services in a cost-effective way. We offer a wide range of services, such as laser cutting, CNC machining, welding and assembly. Our commitment to quality and timely delivery ensures that their products meet the highest industry standards. Prototek’s excellent customer service is responsive and knowledgeable, always willing to satisfy your requirements. Trust Prototek as your reliable partner for sheet metal prototyping.