High-Quality

CNC Routing Parts

Parts in days anywhere in the USA.

CNC Routing is good for:

- Repeatability

- High Dimensional Tolerances

- Custom Prototypes and End-Use Parts

Quality Matters | AS9100D Certified, ISO 9001:2015, ISO 13485:2016, & ITAR Registered

* Not all locations have all certifications and registrations. Parts requiring these will be made at facilities with the correct certifications and registrations.

Table of Contents

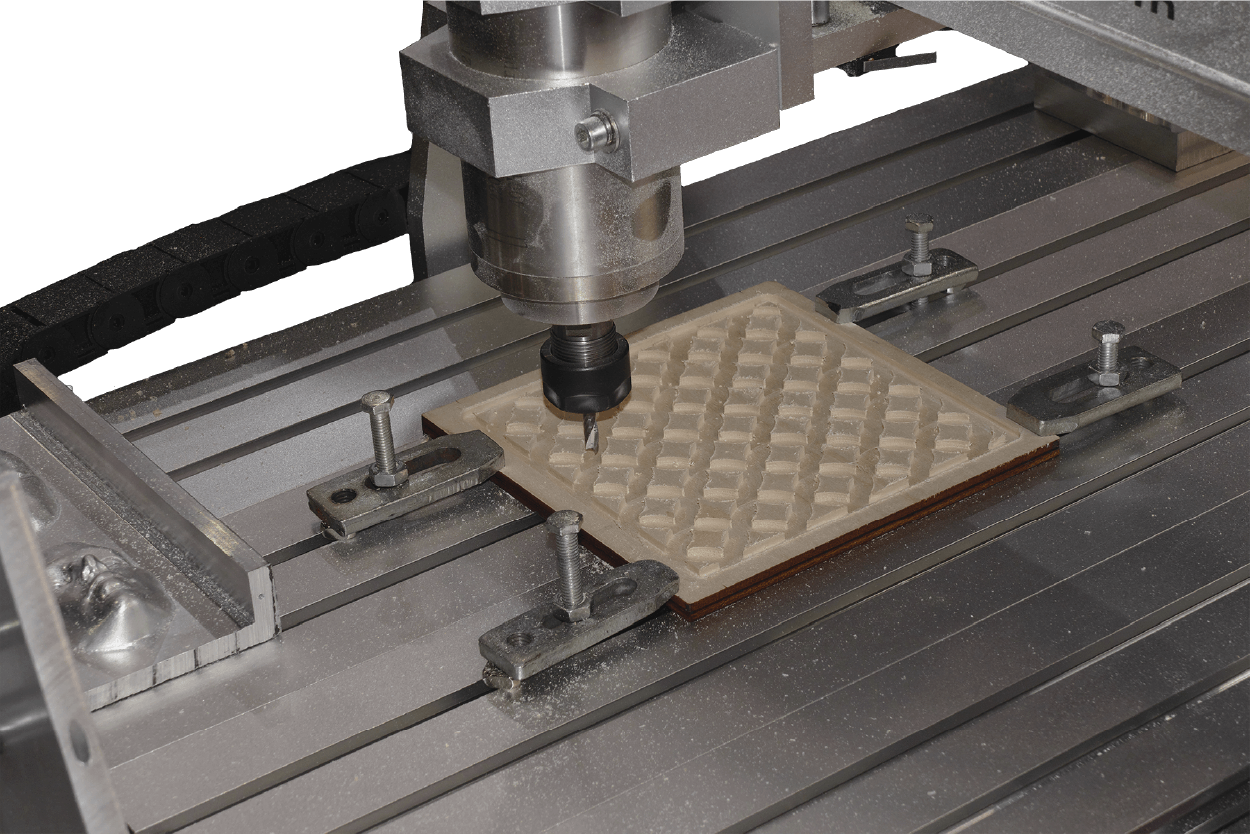

What is CNC Routing?

CNC routing is a manufacturing process that uses computer numerical control (CNC) technology to precisely cut wood, plastic, and metal materials. The process involves using a computer-programmed cutter to remove material from a piece of stock to create a desired shape or design. CNC routers are driven by instructions that tell the machine where to move and how to cut the material. The process is highly efficient and accurate, allowing for highly precise creation of intricate designs and shapes. CNC routing is commonly used in manufacturing, woodworking, sign-making, and other industries where precision cutting is required. It is also a popular choice for creating prototypes and small production runs.

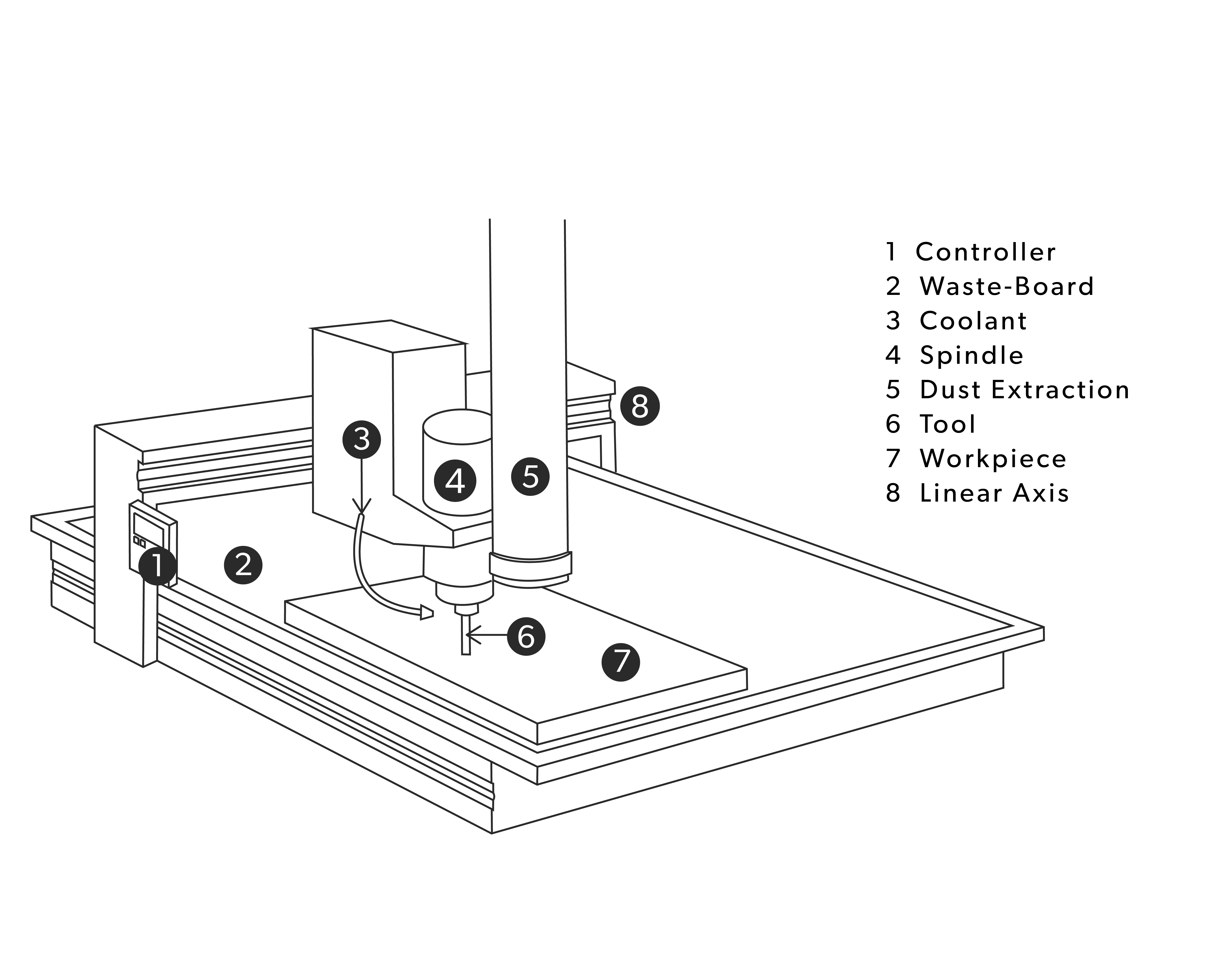

How does CNC Routing work?

CNC routing is a highly advanced manufacturing process that involves the removal of material by cutting and carving with the help of computer-controlled machines. These machines, or CNC (Computer Numerical Control) machines, are programmed to read instructions that guide the cutting and shaping materials such as wood, plastic, and metal into the desired shapes.

The material is carefully positioned on the machine bed for cutting during the routing process. A cutting tool, such as a router or spindle, moves along pre-programmed paths to cut and shape the material according to design specifications. The cutting process involves rotating the cutting tool, which comes into contact with the material. Depending on the design, the tool may make several passes to create the desired shape or cut.

CNC routing is a highly efficient and precise process that can be repeated accurately. It is widely used in manufacturing to create furniture, cabinetry, signage, and industrial parts.

CNC Routing at Prototek

OEM:

KOMO

Lead Time:

14 Days

Max Dimensions:

48 x 120 in

Material:

Plastic, composites, wood, soft metals.

Tolerances:

± 0.005 in

Prototek's Materials for CNC Routing

Metals

When it comes to CNC routing, soft metals are a popular choice due to their high machinability. Aluminum, brass, and copper are the most commonly used soft metals. These metals are known for their relatively low hardness, making them easy to cut, shape, and form. Additionally, they offer good thermal conductivity and are corrosion-resistant, making them suitable for a wide range of applications. For instance, aluminum is widely used in aircraft construction, while brass is often used for decorative purposes and in musical instruments. On the other hand, copper is often used in electrical wiring and the production of heat exchangers.

Other Materials

CNC routing is a versatile process that can work with a wide range of materials. Wood is the most commonly used material in CNC routing due to its easy cutting, shaping, and carving capabilities. However, other popular wood-based materials like MDF are denser and more uniform than natural wood, making them ideal for intricate designs.

CNC routing can also be done with plastic materials like acrylic, polycarbonate, and PVC, often used for signs, displays, and enclosures. These materials are durable, lightweight, and have a smooth surface that is great for printing and painting.

Composites and laminates, such as fiberglass, carbon fiber, and reinforced plastics, can also be CNC routed. These strong and lightweight materials make them ideal for aerospace, automotive, and marine applications.

In summary, CNC routing is a versatile process that can work with an extensive range of materials, including wood, plastics, composites, laminates, and specialized materials. The possibilities are endless, and the results are precise and consistent, making it an ideal process for various industries.

Designing Parts for Routing

When designing parts for CNC routing, several factors require careful consideration. First, you must select the right software and CAD tools to create your design. Once you have your plan, optimizing it for CNC routing is essential. This means ensuring all your curves can be routed without sharp corners or tight turns. You also need to account for the thickness of the material you’ll be using and the bit size of your router.

It’s crucial to remember that CNC routing is a subtractive process, meaning the bit will remove material from the substrate. As a result, you should consider how your design can make the most of the available material while minimizing waste. Also, you’ll need to consider post-processing and finishing options to ensure your parts are ready for their intended use.

Considering these factors, you can design parts optimized for CNC routing, producing high-quality and efficient manufacturing.

Finishes for Machined Components

CNC-routed metal and plastic parts can be finished using various methods depending on the desired outcome. A popular finish for metal parts is powder coating, which provides a durable, corrosion-resistant coating that can be applied in multiple colors and finishes. Anodizing is also a standard finish for metal parts, creating a protective layer that enhances appearance while increasing resistance to wear and corrosion. Other finishes for metal parts include plating, painting, and polishing.

Plastic parts can be finished using paint, which can be done in any color and finish, including glossy, matte, or metallic. Plating is another popular finish for plastic parts, which applies metallic finishes such as aluminum and chrome, creating a reflective surface.

Overall, the choice of finish will depend on the desired outcome and the material being used, and a skilled CNC operator will be able to suggest the best option based on the project requirements.

Why choose Prototek for your next CNC routing project?

Choose Prototek for your next CNC routing project and enjoy the benefits of more than 30 years of experience in providing top-quality precision machined parts and assemblies. Our team of experienced engineers and machinists is dedicated to providing exceptional service. We use state-of-the-art CNC equipment and software to produce high-quality components that meet specifications. We offer in-house services, including CNC routing, milling, turning, and sheet metal fabrication. This means faster turnaround times and lower costs for you. Partner with Prototek for your next CNC routing project; we will provide only the highest quality parts and services.