High-Quality

Hardware Inserts

& Assembly

Parts in days anywhere in the USA.

Hardware Inserts & Assembly offers:

- Combination of Parts for Prototypes and End-Use Products

- Quality Hardware Inserts

- Serial Production Runs as Needed

Quality Matters | AS9100D Certified, ISO 9001:2015, ISO 13485:2016, & ITAR Registered

* Not all locations have all certifications and registrations. Parts requiring these will be made at facilities with the correct certifications and registrations.

Table of Contents

What is Hardware Inserts & Assembly?

Hardware inserts and assembly are critical components in the manufacturing process of various parts. Hardware inserts, such as nuts and bolts, add strength and provide a more secure fastening option. This allows for integrating complex assemblies that require strong joints or connections. Assembly is attaching different components to form a complete product. Assembly ensures that parts are interconnected correctly and function as intended. Hardware inserts and assembly are essential because they enhance the final product’s performance, reliability, and quality. This also saves time and money as parts that require assembly are easier to handle, ship, and install. In conclusion, hardware inserts and assembly are crucial for precise and reliable parts manufacturing.

Types of Hardware Inserts

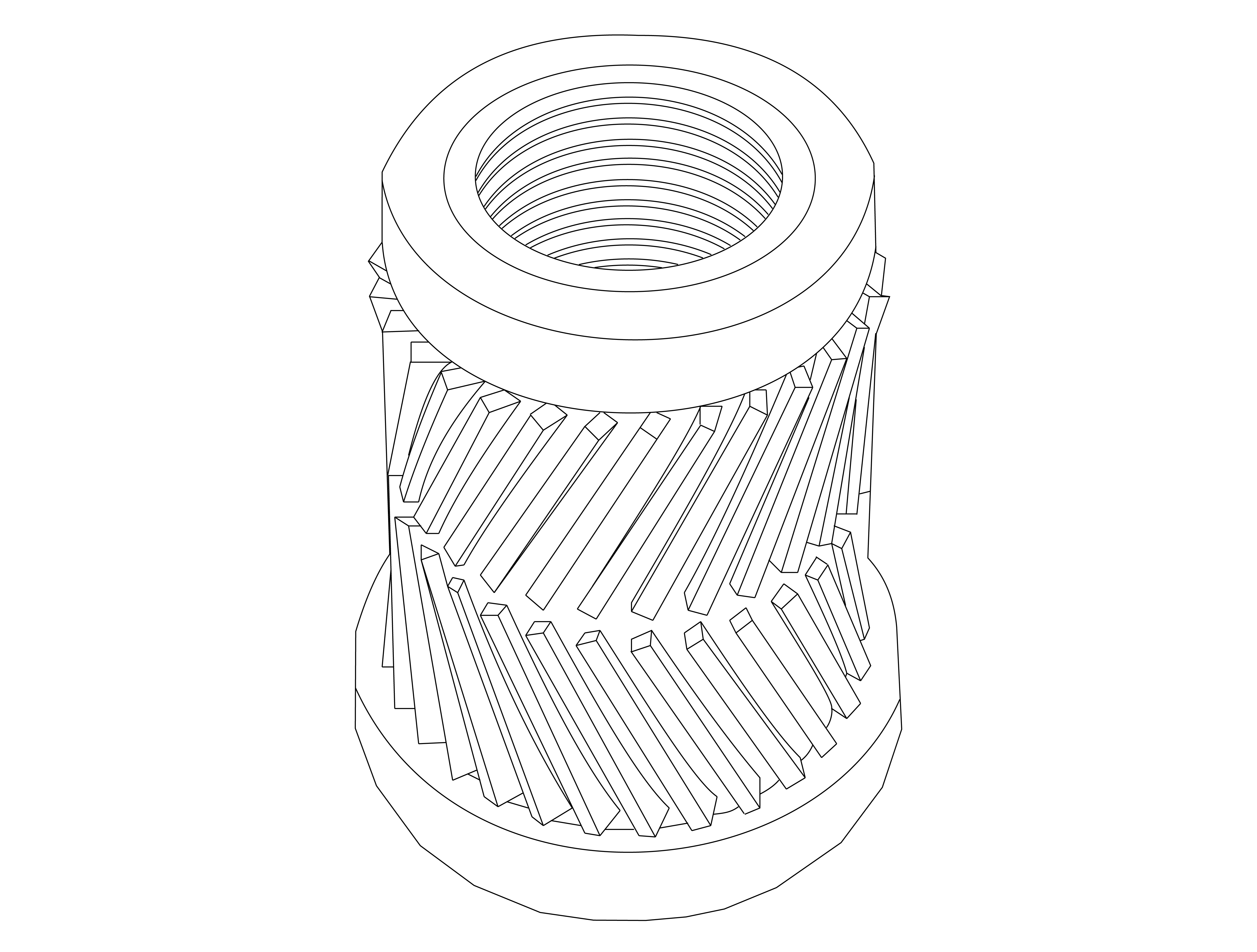

Hardware inserts are components inserted into manufactured parts to enhance their functionality or structure. Several hardware inserts are used in manufacturing, including threaded inserts, press-fit inserts, heat-set inserts, and injection-molded inserts.

Threaded inserts provide threaded connections like heli-coil and self-tapping. Press-fit inserts are pushed or pressed into the part, and the snug fit helps secure the insert. Heat-set inserts are placed in pre-drilled holes and then heated, which melts the plastic around the insert, securing it in place. Injection-molded inserts are molded into the part where the molten plastic flows around the insert, providing a secure fit.

Hardware inserts are used in various industries for different purposes. They enhance the quality, strength, and reliability of the part or component while increasing their lifespan.

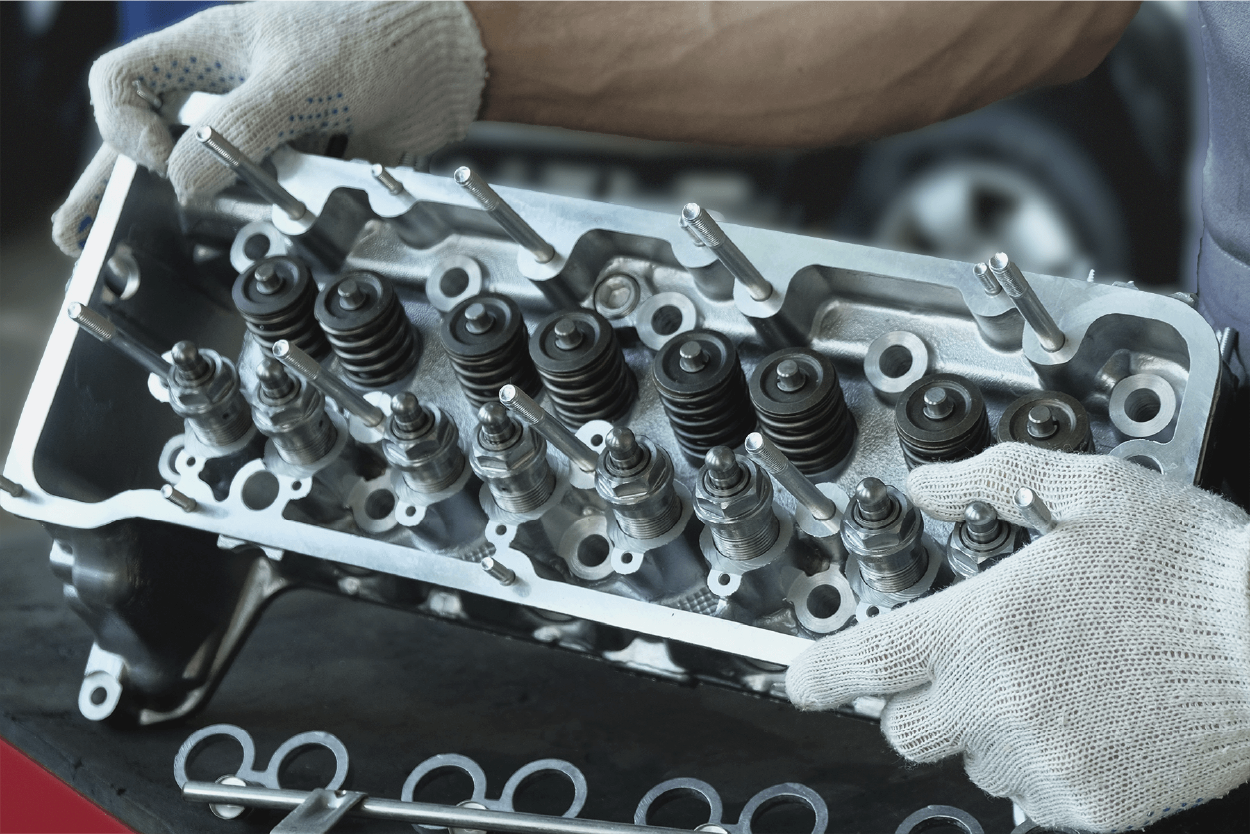

Component Assemblies

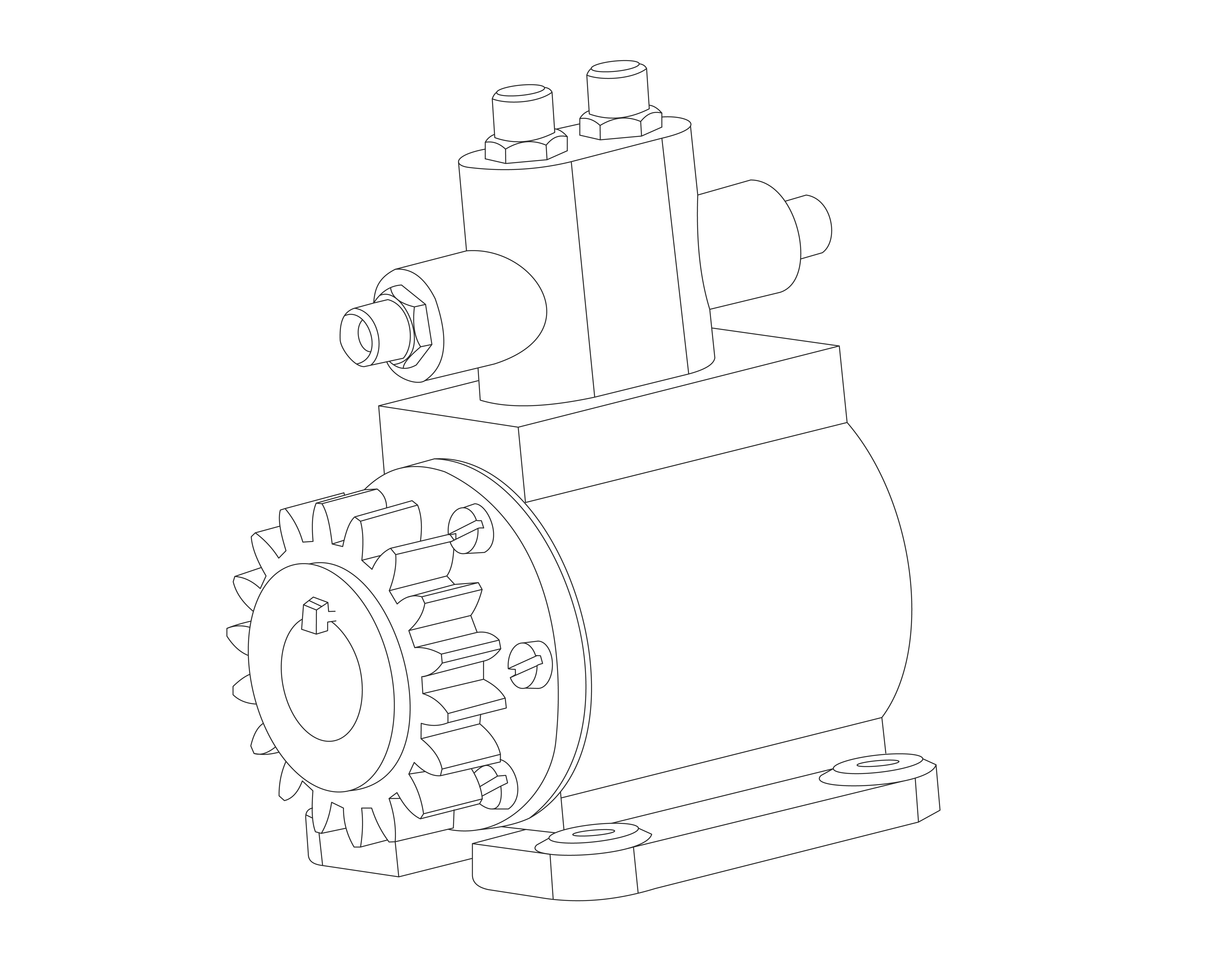

Assembling manufactured components involves making various parts or pieces of a product to create a finished product. The assembling process may be done manually, depending on the complexity of the product. The method of assembling manufactured components is usually the final stage in the production process. It involves gathering various elements such as nuts, bolts, gears, and other smaller parts to create a finished product. Careful attention to detail ensures all components are correctly fitted and the final product meets the desired quality standards. Assembly may be done in-house or outsourced to specialized companies for complex products that require specific expertise. The proper group is vital to successfully manufacturing products, ensuring they function as intended and meet the end-user’s expectations.

Designing Components with Hardware Inserts & Assembly

Hardware Inserts

Hardware inserts are a valuable addition to any project as they provide a quick and secure way of attaching external components. They are typically made of metal or plastic. They can be encased in the material of your project during the production process, providing a solid foundation for attaching screws, bolts, or other hardware components.

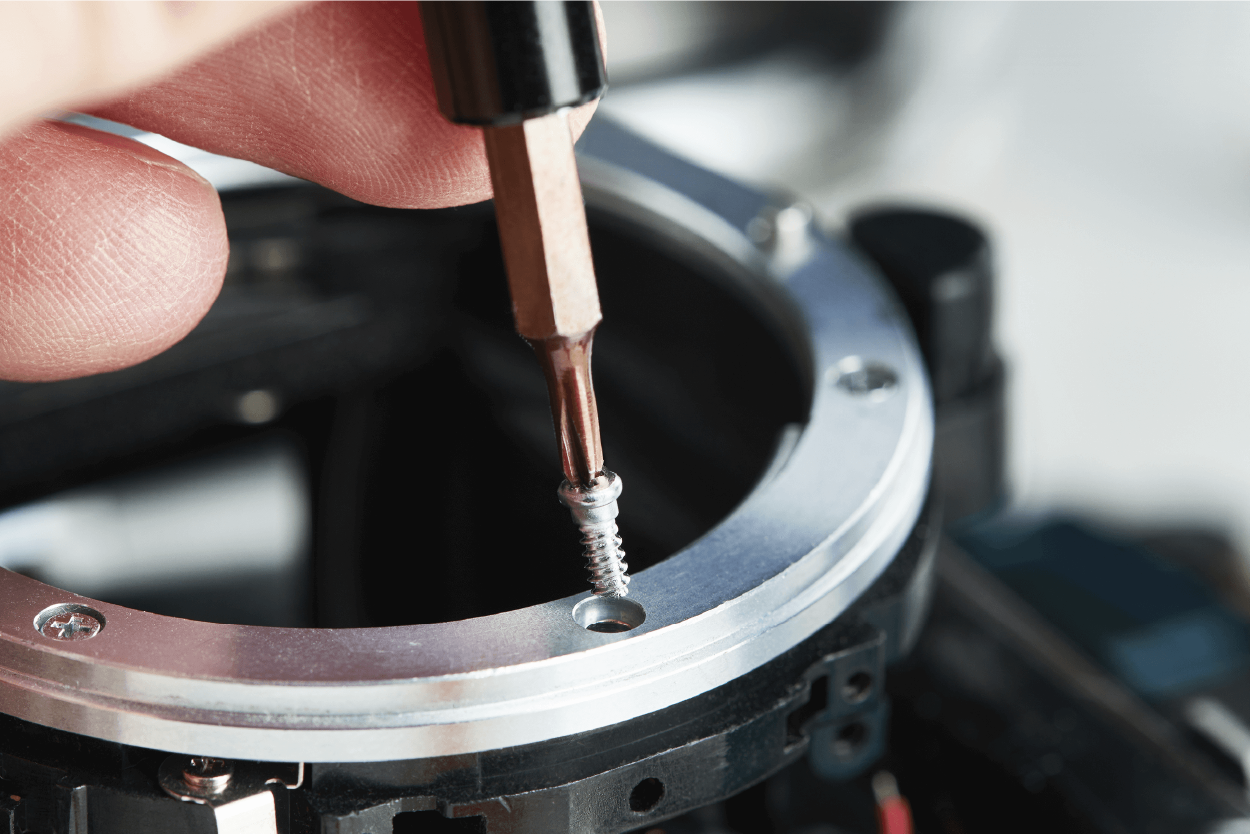

Adding hardware inserts to your project is a straightforward process that can significantly improve your design’s overall durability and functionality. The first step is to choose the right type of insert for your application, considering the size, shape, and material of the external component you wish to attach. Once you have selected the appropriate hardware insert, you must create a hole or cavity in your project to accommodate the insert. The insert is then placed into the hole and secured with adhesive or by heating the surrounding material to melt it around it.

By incorporating hardware inserts into your project, you can create a more robust, reliable design that can withstand heavy usage and extreme conditions. Additionally, inserts can simplify the assembly process, saving time and reducing the risk of errors.

Assembly

Designing a manufacturing project that involves assembly can be both challenging and exciting. There are a few things that you can do to make the process a lot smoother, efficient, and successful. Your first step is identifying all the parts and components necessary to create a finished product. This will help you determine the assembly process and sequence to assemble everything.

Once you clearly understand your project’s components, it’s time to create an assembly plan. This will be your detailed map of all the steps required for assembly and clear diagrams or images showing how each part fits into the whole. Creating a well-crafted plan will save you time and energy, ensuring that you are making a design that is easy to follow and efficient.

Testing your prototype is crucial to ensuring your practical and user-friendly assembly plan. You may need to adjust your schedule based on your prototype’s performance. To optimize the manufacturing process, consider using lean manufacturing techniques to eliminate unnecessary components or steps. By designing your project according to these guidelines, you can create a product that is easy and cost-effective to assemble while still delivering outstanding results.

Why choose Prototek for your next hardware inserts & assembly project?

Prototek is a premier provider of high-quality hardware inserts and assembly services. With over 30 years of experience, we offer precision machining, fabrication, sheet metal bending, and finishing services. We specialize in prototyping and product development services to help bring our client’s ideas to life. Prototek prioritizes quality and uses state-of-the-art facilities, equipment, and skilled engineers and technicians. Our manufacturing techniques and materials are of the highest quality, and they have outstanding customer service that caters to fast turnaround times, competitive pricing, and excellent communication throughout the manufacturing process. Prototek is the perfect partner for any hardware inserts and assembly project, regardless of complexity or scope.